How We Make Handcrafted Watch Strap from Scratch

At Gunny Straps, we believe that if your watch tells a story, your strap should too. Whether you’re wearing a vintage chronograph or a modern diver, the strap is more than an accessory, it’s an extension of the watch’s personality and yours.

Every Gunny strap is handcrafted from scratch by our in-house team, using a meticulous process that blends traditional craftsmanship with a deeply personal touch. Whether it’s a fully custom design or a signature series, every detail is made by hand, from raw leather selection to final inspection.

Here’s a behind-the-scenes look at how we make handcrafted strap from scratch, step by step.

Leather Selection Process

Choosing the Right Leather for a Good Foundation

Every great strap begins with the right material. We have hundreds of leathers in stock, each with unique textures, colors, and characteristics. Selecting the right leather is crucial, it must match the watch’s design, meet your functional needs, and bring the right aesthetic to the final result.

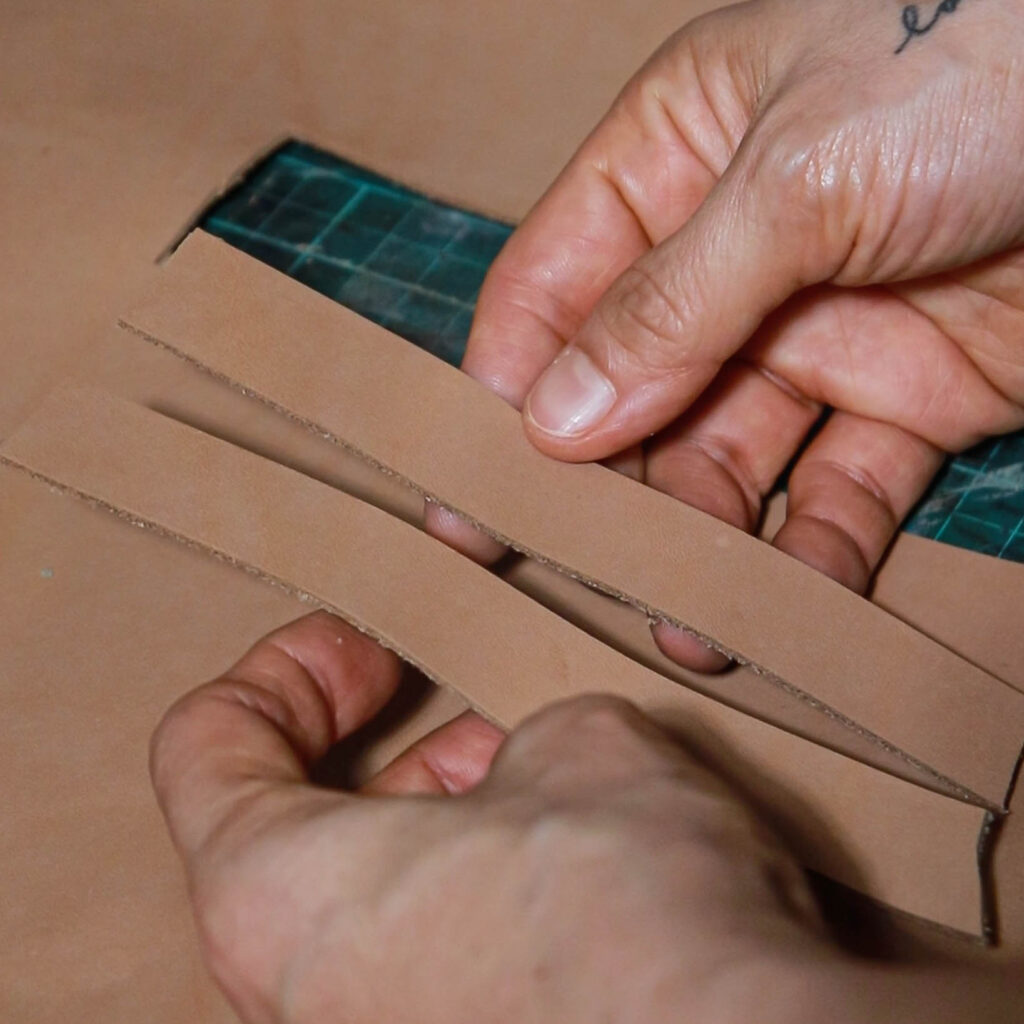

Cutting & Sizing: Precision Starts Here

Once the leather is chosen, we cut it according to your requested dimensions and strap style. The cut must be perfectly clean and proportional—this early precision ensures the final product fits exactly as intended.

Size & Quality Control Check

After cutting, we double-check the dimensions and inspect the leather to ensure it meets our standards. Even the smallest inconsistency is corrected at this stage to ensure the strap will not only look great but wear comfortably.

The Strap Making Process

Skiving: Thinning for Function & Fit

Skiving is the process of thinning the leather, typically at the edges or center where flexibility is needed. This step is adjusted based on the strap’s design, wrist comfort, and intended thickness.

Gluing the Core Layers

We apply adhesive to bind the layers—the outer leather, the lining, and any inner fillers—based on the design’s construction. Clean gluing ensures durability and a tidy assembly.

Assembly & Alignment

Once glued, all components are assembled and aligned carefully. We ensure the strap maintains the correct structure and balance before moving forward.

Tidying & Shape Reinforcement

We check that the assembled strap is still the correct size, shape, and alignment. This step is essential for both comfort and visual symmetry.

Tip Cutting & Making The Strap Holes

Tip Cutting: Defining the Strap Shape

The tip of the strap is cut based on the desired style—square, rounded, or pointed. A well-defined tip gives the strap a finished, professional look.

Creating Strap Holes

We precisely measure hole placement based on your wrist size and strap length. This step is done with care to ensure a perfect fit and balance.

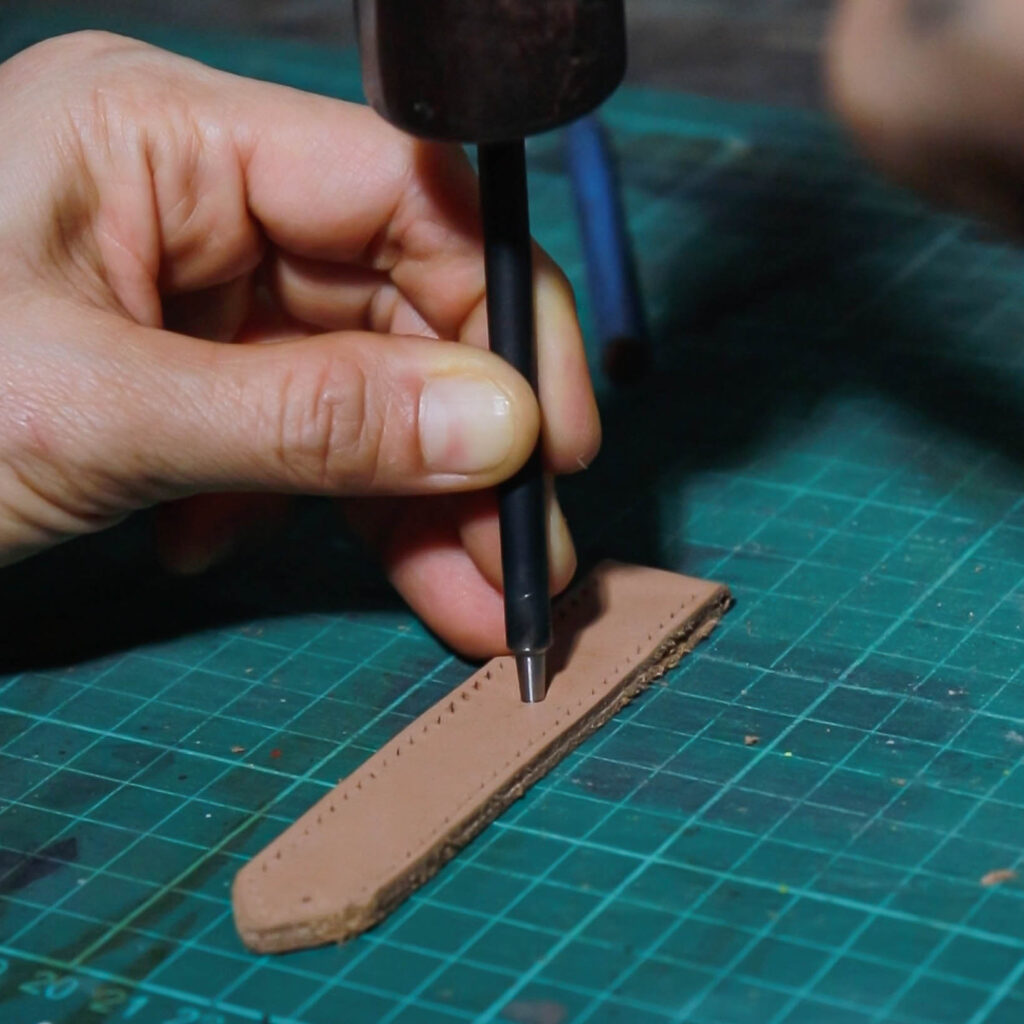

Creating The Stitching Holes

Next, we punch individual holes for hand-stitching, positioned to support both aesthetics and structural strength.

The Finishing Process

Custom Coloring: Hand-Mixed & Hand-Applied

Coloring is one of our favorite parts. We hand-mix every dye in-house, allowing us to create completely custom tones—whether to match your watch, your wardrobe, or your personal style. Multiple layers of coloring are applied for richness and depth.

Strap Finishing: The Signature Gunny Touch

Every strap goes through 5 to 20+ finishing steps, depending on the design. For example, simpler models might require minimal detailing, while complex ones like the Mission Impossible strap go through extensive hand-finishing for texture, tone, and effect.

Hand Stitching: Done Entirely by Hand

All stitching is done entirely by hand, using nothing but needle and thread. We don’t use machines—our artisans stitch each strap with precision, one hole at a time, for a strong and beautiful result.

Edge Finishing: Clean and Precise

We carefully paint and seal the edges of each strap to prevent fraying and enhance visual definition. This step is often overlooked elsewhere, but it’s a detail we never skip.

Final Construction Processes

Attaching Keepers, Buckles, and Spring Bars

We attach the handcrafted keepers, secure the selected buckle, and install the spring bars (quick-release or standard). These final touches complete the structure of the strap.

Final Quality Control: The Last, Most Important Step

Before shipping, every strap undergoes a strict quality control process. We re-check the fit, finish, color, and all details to ensure the strap meets your request perfectly—both in design and execution.

Why Our Process Matters?

Each step above is done by hand, not by machines, not outsourced. This allows us to guarantee not only quality, but authenticity, character, and heart in every piece. Whether you’re ordering a strap to match your vintage Omega or designing something new for your modern Panerai, Rolex, or any other watches, Gunny Straps brings your vision to life through craftsmanship that lasts.